All You Ever Wanted to Know About Anaerobic Digesters: But Were Too Afraid to Ask

By Maria DeKoning

One of the greatest threats to our world today is the changing climate due to the emission of greenhouse gasses (GHGs) into the atmosphere. Of those, the most concerning greenhouse gasses is methane (CH4) which is produced from agriculture, waste management, use of energy, and transportation. To mitigate these GHGs, we must take a step towards developing new technology that reduces these emissions and benefits us even further.

In recent times, the Biden Administration set the goal of fighting climate change and achieving the national food waste targets. These actions have increased incentives across the nation to implement practices that create renewable energy alternatives rather than fossil fuels.

What is Anaerobic Digestion?

Anaerobic digestion (AD) is a series of biological processes in which microorganisms break down biodegradable waste to produce renewable energy. It’s a process that both controls pollution and recovers energy to produce the main product of biogas. This process takes place in a sealed vessel or a reactor.

Companies that would benefit the most from AD are those with high amounts of agricultural and industrial waste. These products are ideal because they contain high levels of easily biodegradable materials.

Organic materials can be combined in a digester to create biogas or by-products such as digestate, fertilizers, and solids that can have a variety of applications. Biogas can be used as a form of energy and is considered a renewable resource. Common uses of this form of energy include electricity, heat, or vehicle fuel.

How are the Products Used?

Biogas is a form of renewable energy that can be utilized in a variety of different ways and is dependent on the quantity at which it is produced.

- Mechanical power, heating, or electricity

- Fuel for vehicles that run on materials other than fossil fuels

- Natural gas pipelines for homes and businesses

When there is a lower amount of biogas being produced, it is typically used to fuel less efficient engines and can be cleaned to create compressed natural gas (CNG) or liquefied natural gas (LNG). Both of these can fuel cars and trucks. Common uses of the by-products are as follows:

- Livestock bedding

- Organic Fertilizers

- Soil for flower pots and beds

Incorporation of the residual products of AD will help improve soil composition and encourage crop growth. There is also the possibility for them to be bagged and sold in stores to substitute chemical fertilizers.

Elimination of Greenhouse Gasses

Anaerobic digestion plays a huge role in the elimination of GHGs that result from organic wastes. The process helps capture methane gas that would have been released into the atmosphere and instead converts it into a usable resource. Methane gas is a GHG that has twenty-one percent more greenhouse gas potential than CO2. One of the best places to incorporate anaerobic digestion is on agricultural lands. Farmlands produce a ton of organic matter that would be perfect to feed an AD. Ways that an AD makes a farm more profitable are as follows:

- Digestate is an accessible form of nutrients to increase plant growth rather than raw materials.

- Nutrient recycling creates an environmentally sustainable production system.

- Production of energy, such as heat fuel and electricity, can be immediately used on the farm and decreases the need for fossil fuel use.

Food Waste

Currently, organic food waste makes up the largest percentage of garbage today. The EPA estimates that 35.3 tons of food waste ended up in landfills in the year 2018. That is roughly 24.1% of all municipal solid waste (MSW) sent to landfills. It is estimated by the EPA that roughly 35 million tons of food waste ends up in landfills. That is 20% of all of the waste produced. Wasted food falls into two main categories, both of them leading to an unsustainable food system and the emission of GHGs.

Food loss refers to the food that goes uneaten. These foods are considered edible but do not end up getting consumed. There is food loss at every stage of food production.

- Crops that are never harvested and are left in the field

- Food that spoils during transportation

- Foods in grocery stores and homes that are never eaten

Food waste is food that is rendered inedible. The US Department of Agriculture (USDA) defines food waste as “food discarded by retailers due to color or appearance and plate waste by consumers.” This is a more specific category but includes food that Is not spoiled, just left uneaten.

- Half-eaten meal on a plate at a restaurant or at home

- Food scraps leftover from cooking

- Sour milk poured down the drain

Between 35-50% of food that is produced is never even eaten and results in an extreme market failure. The amount of food that is wasted adds up to one trillion dollars and represents 1.3% of the total GPD. It all comes down to perfectly fine food getting discarded every day in the U.S. Food waste originates from multiple different areas, but it all ends up in landfills and incinerators that contribute to methane emissions. There are countless ways that food gets lost, but that does not mean that there is nothing we can do about it.

The addition of AD to areas that have large amounts of food loss would create an increased revenue and create an opportunity for a more sustainable food system.

Galli Engineering’s Role in Anaerobic Digestion

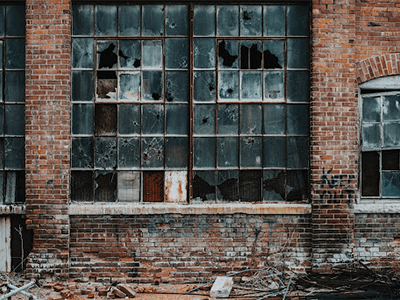

The demand for better waste management has become apparent in the current day. To improve the system, we must upgrade our traditional practices. Instead of formulating a plan for new landfills or more proficient incinerators, Galli Engineering has spearheaded a project with Global Water & Energy (GW&E) to divert waste materials from landfills and incinerators. The goal of the project is to turn these waste materials into an affordable energy alternative.

The project is set to take place in LaPorte County, Indiana in the town of Kingsbury. The AD will process 200-400 tons of source-separated food waste per day at the proposed location of the LaPorte County Commercial Plant. It will produce Renewable and Compressed Natural Gas (RNG and CNG) and fertilizer. The project is looking to create 60 permanent jobs for experienced locals and roughly 100 construction jobs.

RNG is a sustainable and clean burning transportation tool. It has a lower carbon content and releases the fewest amount of emissions compared to all other fuels.

LaPorte County, Indiana is the optimal location of AD because of the large amounts of agricultural waste and its proximity to abundant food waste in the area. The food waste that supplies the system will be converted into useful products that can serve the area efficiently.

Galli Engineering looks to stay ahead of the difficult issues and looks to find ways to mitigate them for an easier and healthier life for all. To read more about what Galli Engineering is working on and researching, visit the website and new blog page.